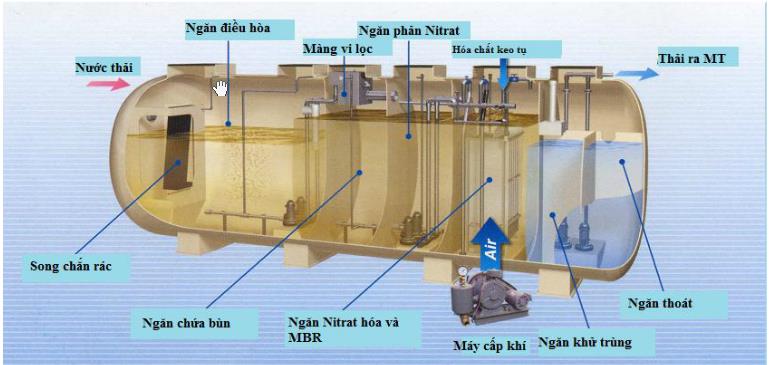

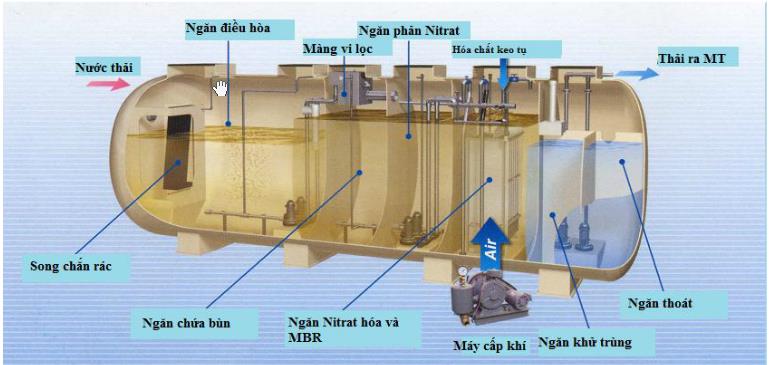

Diagram of technology of domestic wastewater treatment

June 29 2019

689 View

Domestic wastewater from residential areas after preliminary treatment in septic tanks will be collected to the concentrated domestic wastewater treatment system. Part of the large-scale coarse debris such as nylon bags, rags, twigs, paper ... is kept in place but the garbage is removed to avoid damaging or blocking the pump and subsequent works. Recovered rubbish is taken away for disposal. Domestic waste water after passing through the barrier will continue through the receiving compartment before going through the regulating tank.

Here, the tank will attach an aeration system to reduce the fluctuation of the content of contaminants in the water due to uneven discharge process, stabilize flow and concentration, avoid overloading at peak hours , thus helping the system to handle stable work while reducing the size of subsequent unit works.

Waste water continues to be brought to SBR tank. SBR is a form of biological sludge treatment with activated sludge, which takes place in the process of blowing air, sludge settling and decanting of waste water. Activated sludge is actually microorganisms so when mixed with waste water with air with oxygen, they decompose organic substances into sediment and will settle down in SBR tank. The water in the SBR tank is removed from the tank by means of collecting surface water after leaving the tank and finally before discharging it into the natural source, the water is added to the disinfection tank to disinfect the water..jpg)

Treatment of domestic wastewater in modular form

Modular tank for domestic wastewater treatment

After passing the SBR tank, the wastewater is directed to the disinfection tank without going through the settling tank. Disinfect by adding chlorine disinfectant. Waste water after sterilization meets QCVN 14: 2008 / BTNMT, column B will be discharged into the regional drainage system. The part of sludge to be treated is put into the reservoir and the sludge is compressed. Mud generated with very high humidity. The task of slurry compaction tank is to reduce the moisture content of the sludge by settling (compressing) mechanically to achieve the proper moisture content (94 - 96%) for the treatment of sludge in the back.

In this technology, the sludge gravity compression method is introduced into the sludge distribution tube in the center of the tank. Under gravity, the mud will settle and bind. After compression, the mud will be removed at the bottom of the tank. The slurry water is returned to the receiving compartment.

Sludge from the slurry tank is brought to the press. After getting out of the mud press, the mud is in the form of a cake and is then taken away for burial. Water from the sludge press is returned to the collection pit to be reprocessed.

Here, the tank will attach an aeration system to reduce the fluctuation of the content of contaminants in the water due to uneven discharge process, stabilize flow and concentration, avoid overloading at peak hours , thus helping the system to handle stable work while reducing the size of subsequent unit works.

Waste water continues to be brought to SBR tank. SBR is a form of biological sludge treatment with activated sludge, which takes place in the process of blowing air, sludge settling and decanting of waste water. Activated sludge is actually microorganisms so when mixed with waste water with air with oxygen, they decompose organic substances into sediment and will settle down in SBR tank. The water in the SBR tank is removed from the tank by means of collecting surface water after leaving the tank and finally before discharging it into the natural source, the water is added to the disinfection tank to disinfect the water.

.jpg)

Treatment of domestic wastewater in modular form

Modular tank for domestic wastewater treatment

After passing the SBR tank, the wastewater is directed to the disinfection tank without going through the settling tank. Disinfect by adding chlorine disinfectant. Waste water after sterilization meets QCVN 14: 2008 / BTNMT, column B will be discharged into the regional drainage system. The part of sludge to be treated is put into the reservoir and the sludge is compressed. Mud generated with very high humidity. The task of slurry compaction tank is to reduce the moisture content of the sludge by settling (compressing) mechanically to achieve the proper moisture content (94 - 96%) for the treatment of sludge in the back.

In this technology, the sludge gravity compression method is introduced into the sludge distribution tube in the center of the tank. Under gravity, the mud will settle and bind. After compression, the mud will be removed at the bottom of the tank. The slurry water is returned to the receiving compartment.

Sludge from the slurry tank is brought to the press. After getting out of the mud press, the mud is in the form of a cake and is then taken away for burial. Water from the sludge press is returned to the collection pit to be reprocessed.

Comments